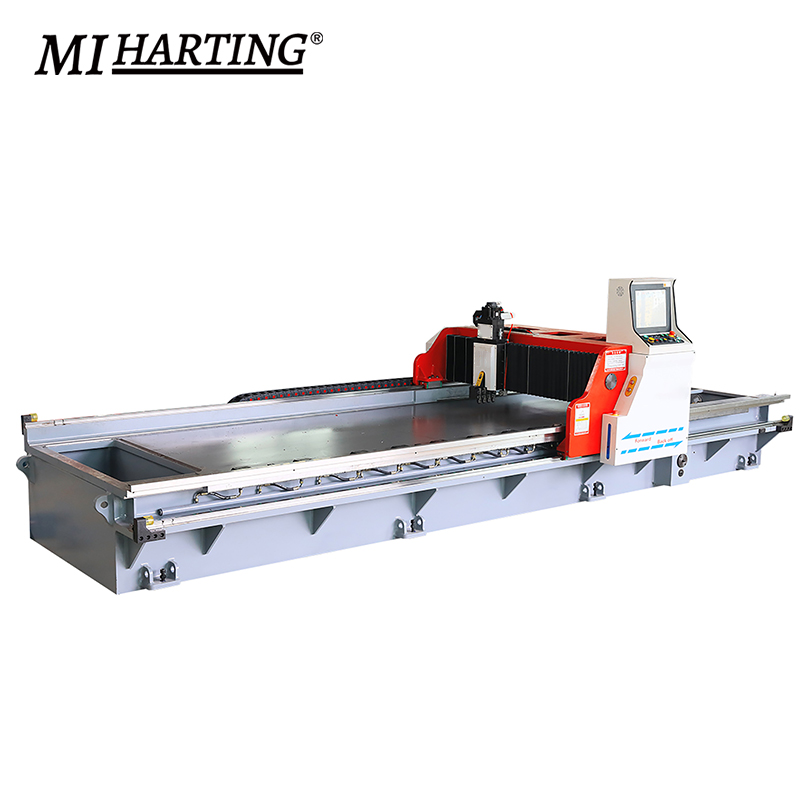

تُستخدم آلات الحفر على شكل حرف V لإنشاء أخاديد أو أخاديد في مواد مثل المعدن أو البلاستيك أو الخشب والتي تُستخدم غالبًا في الانحناء أو التجميع. الخامس الأخدودآلات التصنيع يُسهّل عملية الثني ويجعلها أكثر دقة. عند استخدام آلة حفر على شكل حرف V للمعالجة، من المهم اتباع إجراءات التشغيل لضمان الدقة والسلامة. فيما يلي طريقة عامة لاستخدام آلة حفر على شكل حرف V:

تحضير

تحقق من إعدادات ماكينة الحفر على شكل حرف V: قبل بدء التشغيل، تأكد من الخامس آلة الحفر تم معايرة الأخدود بدقة وضبطه على عمق الأخدود المطلوب. اضبط حجم الأخدود على شكل حرف V وفقًا لسمك المادة.

اختر الأداة المناسبة: تأكد من أن أداة القطع حادة ومناسبة للمادة التي تُعالجها. من الأدوات الشائعة شفرات الكربيد للمعادن وأدوات الماس للبلاستيك.

إعداد المواد: ضع المادة بإحكام على طاولة العمل، ووازنها جيدًا مع قضبان التوجيه لآلة الحفر على شكل حرف V. تأكد من تثبيت المادة بإحكام لتجنب حركتها أثناء القطع.

تشغيل آلة الحفر على شكل حرف V

شغّل آلة حفر الأخدود على شكل حرف V وتأكد من عملها بسلاسة. ابدأ بسرعة منخفضة، ثم زدها تدريجيًا حسب نوع المادة وعمق الأخدود.

سرعة التغذية: اضبط سرعة التغذية المناسبة حسب المادة. عادةً ما تكون سرعة التغذية أقل للمعادن، بينما قد تتطلب المواد البلاستيكية سرعة أعلى.

عمق القطع: اضبط عمق القطع بناءً على سُمك المادة. قد يتطلب الأمر قطعًا متعددة للأخاديد العميقة.

عملية الحفر: مرر المادة تحت قاطع آلة الحفر على شكل حرف V مع تثبيت القاطع. سيُشكّل القاطع أخدودًا على شكل حرف V على سطح المادة.

التفتيش وفحص الجودة

فحص الأخدود: بعد القطع، تحقق من عمق وعرض الأخدود للتأكد من مطابقته للمواصفات. يجب أن يكون الأخدود نظيفًا وخاليًا من النتوءات أو العيوب.

اختبار الانحناء: إذا تم استخدام الأخدود V للانحناء، فاختبر مرونة المادة للتأكد من أن الأخدود عميق بما يكفي للانحناء بسهولة دون إتلاف المادة.

تنظيف وصيانة آلة الحفر على شكل حرف V

تنظيف آلة الحفر على شكل حرف V: بعد الاستخدام، نظّف آلة الحفر على شكل حرف V لإزالة أي حطام أو مواد متبقية. هذا يمنع تلف الأداة ويضمن أداءً مثاليًا للعمليات المستقبلية.

فحص الأداة: افحص أداة القطع بانتظام للتأكد من عدم تآكلها. استبدلها عند الحاجة للحفاظ على دقة قطع عالية.

التزييت: إذا كانت ماكينة الحفر على شكل حرف V الخاصة بك تتطلب التزييت، قم دائمًا بتزييت الأجزاء المتحركة لتقليل الاحتكاك ومنع التآكل المبكر.

نصائح السلامة

ارتدِ معدات الحماية: ارتدِ دائمًا نظارات السلامة والقفازات وسدادات الأذن عند تشغيل آلة الحفر على شكل حرف V.

اتبع إرشادات الشركة المصنعة: اتبع دائمًا دليل المشغل وتعليمات السلامة المقدمة من قبل الشركة المصنعة. مُصنِّع آلات الحفر على شكل حرف V .

تجنب التحميل الزائد: لا تقم أبدًا بتحميل آلة الحفر على شكل حرف V بكمية من المواد أكبر مما يمكنها حمله، حيث قد يؤدي ذلك إلى وقوع حادث أو تلف الآلة.

هذه إرشادات عامة فقط، وقد تختلف باختلاف طراز آلة الحفر على شكل حرف V التي تستخدمها. يُرجى دائمًا مراجعة دليل الشركة المصنعة لمزيد من التعليمات التفصيلية الخاصة بمعداتك.