FEATURES

- OVERALL WELDED AND PROCESSED STRUCTURE, THE FRAME IS ANALYZED USING ANSYS FINITE ELEMENT ANALYSIS SOFTWARE TO ENSURE THE RELIABILIT OF THE MACHINE AND THE PRECISION OF THE MACHINE.

- ELECTRIC HYDRAULIC PROPORTIONAL SERVO SYNCHRONIZATION, ENSURING REPEATED ACCURACY.

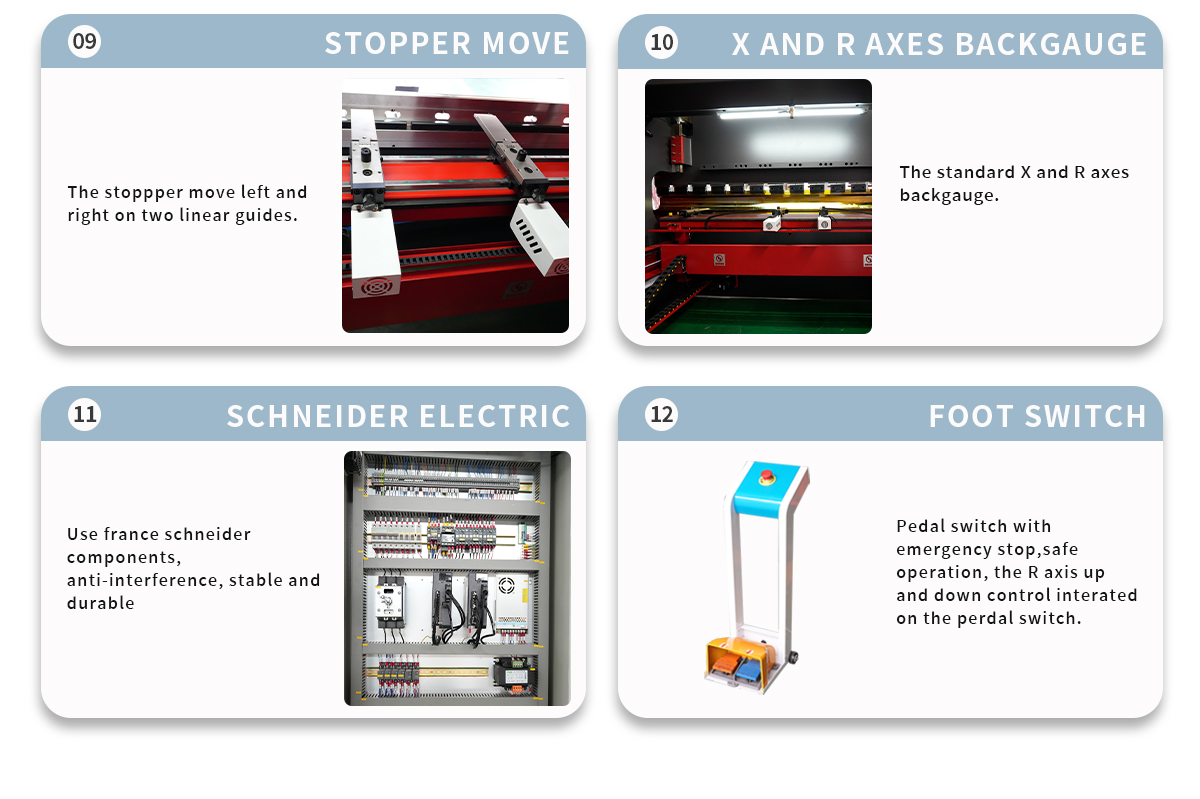

- THE STANDARD 4+1 AXES, IMPORTED BALL SCREW AND LINEAR GUIDE RAIL ENSURE THE SPEED AND ACCURACY OF THE BACKGAUGE, AND MORE MULTI-AXES BACKGAUGE MECHANISM CAN BE USED ACCORDING TO CUSTOMER REQUIREMENTS.

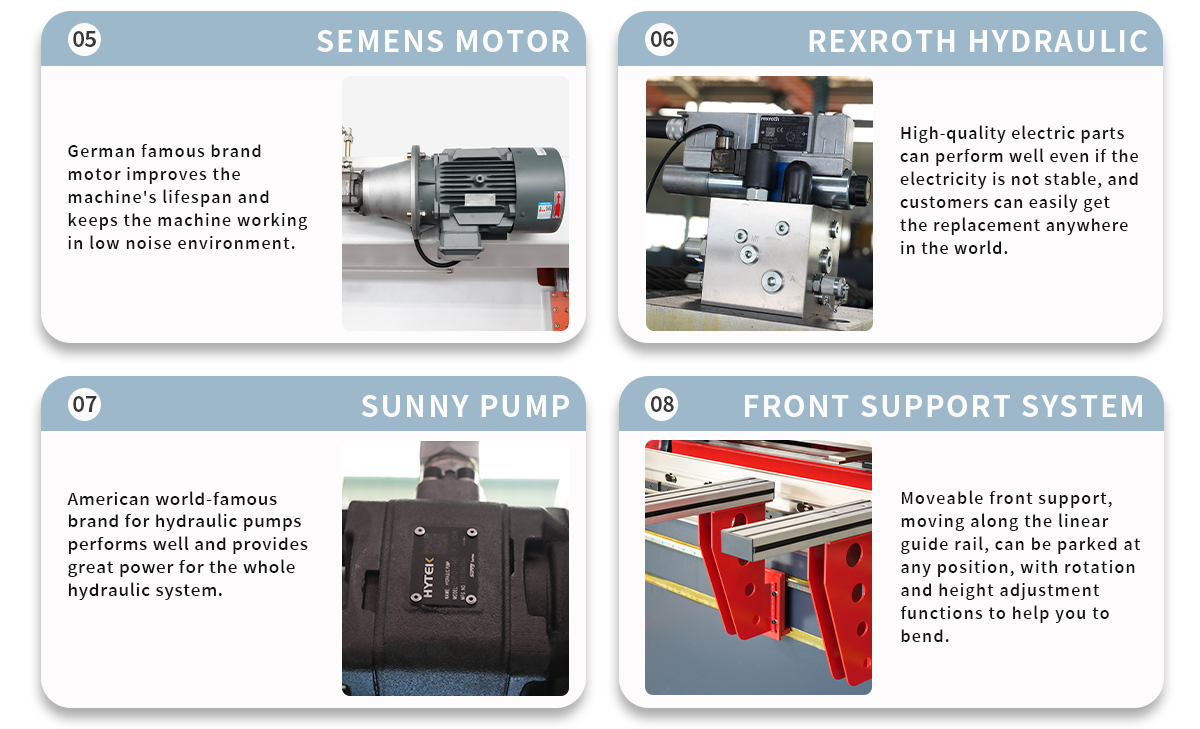

- THE HYDRAULIC SYSTEM ADOPTS THE INTEGRATED CONTROL SYSTEM IMPORTED FROM GERMANY, WHICH REDUCES THE INSTALLATION OF PIPELINES, ENSURES THE STABILITY OF THE MACHINE, AND THE APPEARANCE IS SIMPLE AND BEAUTIFUL.

- C-TYPE PLATES ARE INSTALLED ON BOTH SIDES OF THE MACHINE FRAME, AND THE HIGH-PRECISION GRATING RULER IS MOUNTED ON THE C-TYPE PLATE SO AS TO AVOID THE INFLUENCE OF DEFORMATION OF THE FUSELAGE ON THE BENDING ACCURACY DURING BENDING.

- AUTOMATIC MECHANICAL CROWING MECHANISM ELIMINATE THE INFLUENCE OF SLIDER DEFORMATION ON WORKPIECE QUALITY. CNC CONTROLLER AUTOMATICALLY ADJUSTS THE COMPENSATION AMOUNT, AND THE OPERATION IS CONVENIENT AND ACCURATE.

- SPECIAL CNC CONTROLLER NORMALLY USES HOLLAND DELEM, ITALY ESA, SWISS CYBELEC.

CNC CONTROL SYSTEM

•"HOT-KEY^ TOUCH NAVIGATION

•10.1° HIGH RESOLUTION COLOUR TFT

•UP TO 4 AXES (Y1,Y2 + 2 AUX. AXES)

•CROWNING CONTROL

•TOOL / MATERIAL / PRODUCT LIBRARY

•SERVO AND FREQUENCY INVERTER CONTROL

•ADVANCED Y-AXIS CONTROL ALGORITHMS FOR CLOSED- LOOP AS WELL AS OPEN-LOOP VALVES.

•TANDEMLINK (OPTION)

•USB MEMORY STICK INTERFACING

•PROFILE-T OFFLINE SOFTWARE

•2D GRAPHICAL TOUCH SCREEN PROGRAMMING

•15° HIGH RESOLUTION COLOUR TFT

•BEND SEQUENCE CALCULATION

•CROWNING CONTROL

•SERVO AND FREQUENCY INVERTER CONTROL

•ADVANCED Y-AXIS CONTROL ALGORITHMS FOR CLOSED LOOP ASWELL AS OPEN-LOOP VALVES.

•USB, PERIPHERAL INTERFACING

•PROFILE-T OFFLINE SOFTWARE

•2D GRAPHICAL TOUCH SCREEN PROGRAMMING MODE

•3D VISUALISATION IN SIMULATION AND PRODUCTION

•17° HIGH RESOLUTION COLOUR TFT

•FULL WINDOWS APPLICATION SUITE

•DELEM MODUSYS COMPATIBILITY (MODULE SCALABILITY AND ADAPTIVITY)USB, PERIPHERAL INTERFACING

•USER SPECIFIC APPLICATION SUPPORT WITHIN THE CONTROLLERS MULTITASKING ENVIRONMENT

•SENSOR BENDING & CORRECTION INTERFACE

•PROFILE-TL OFFLINE SOFTWARE

•3D AND 2D GRAPHICAL TOUCH SCREEN PROGRAMMING MODE

•3D VISUALISATION IN SIMULATION AND PRODUCTION

•17° HIGH RESOLUTION COLOUR TFT

•FULL WINDOWS APPLICATION SUITE

•DELEM MODUSYS COMPATIBILITY (MODULE SCALABILITY AND ADAPTIVITY) USB, PERIPHERAL INTERFACING

•USER SPECIFIC APPLICATION SUPPORT WITHIN THE

•CONTROLLERS MULTITASKING ENVIRONMENT

•SENSOR BENDING & CORRECTION INTERFACE

•PROFILE-T3D OFFLINE SOFTWARE

•ANGLEPROGRAMMING

•MULTI-STEP PROGRAMMING

•TOOL LIBRARY

•THE OPENING HEIGHT OF EACH STEP IS PROGRAMMABLE

•MULTI-AXIS EXPANSION X-AXIS,Y1-AXIS,Y2-AXIS,R-AXIS AND C-AXIS

•SUPPORT MAGNETIC SCALE

•LARGE ARC FUNCTION

•MATERIAL LIBRARY,PLATE LENGTH,PLATE THICKNESS,ETC.

•40 PROGRAMS,25STEPS PER PROGRAM

•BACKGAUGE CONTROL

•CONTROL THE COMMON MOTOR OR INVERTER

•HOLDING PRESSURE UNLOADING TIME SETTING

•WORKPIECE COUNTING

•40 PROGRAMS STORED, 25 STEPS PERPROGRAM

•CONCESSION FUNCTION

| Type( WE67K series) | Nominal Force (KN) | Bending Length (mm) | Poles distance(mm) | Throat Depth(mm) | Slider Travel(mm) | Die Loading Height(mm) | Main Motor Power(kw) | Axes | Compensation cylinders |

| 63T/2500 | 630 | 2500 | 1900 | 350 | 170 | 380 | 5.5 | 4+1 | 2 |

| 80T/3200 | 800 | 3200 | 2700 | 350 | 170 | 380 | 7.5 | 4+1 | 3 |

| 100T/3200 | 100 | 3200 | 2700 | 400 | 200 | 420 | 7.5 | 4+1 | 3 |

| 160T/3200 | 1600 | 3200 | 2700 | 400 | 200 | 420 | 11 | 4+1 | 3 |

| 200T/3200 | 2000 | 3200 | 2700 | 400 | 200 | 420 | 15 | 4+1 | 3 |

| 250T/3200 | 2500 | 3200 | 2700 | 400 | 200 | 420 | 15 | 4+1 | 3 |

| 320T/3200 | 3200 | 3200 | 2700 | 400 | 200 | 420 | 22 | 4+1 | 3 |

| 400T/4000 | 4000 | 4000 | 3500 | 400 | 320 | 420 | 30 | 4+1 | Mechanical |

| 500T/5000 | 5000 | 5000 | 3900 | 500 | 320 | 600 | 37 | 4+1 | Mechanical |

| 600t/5000 | 6000 | 5000 | 3900 | 500 | 320 | 600 | 45 | 4+1 | Mechanical |