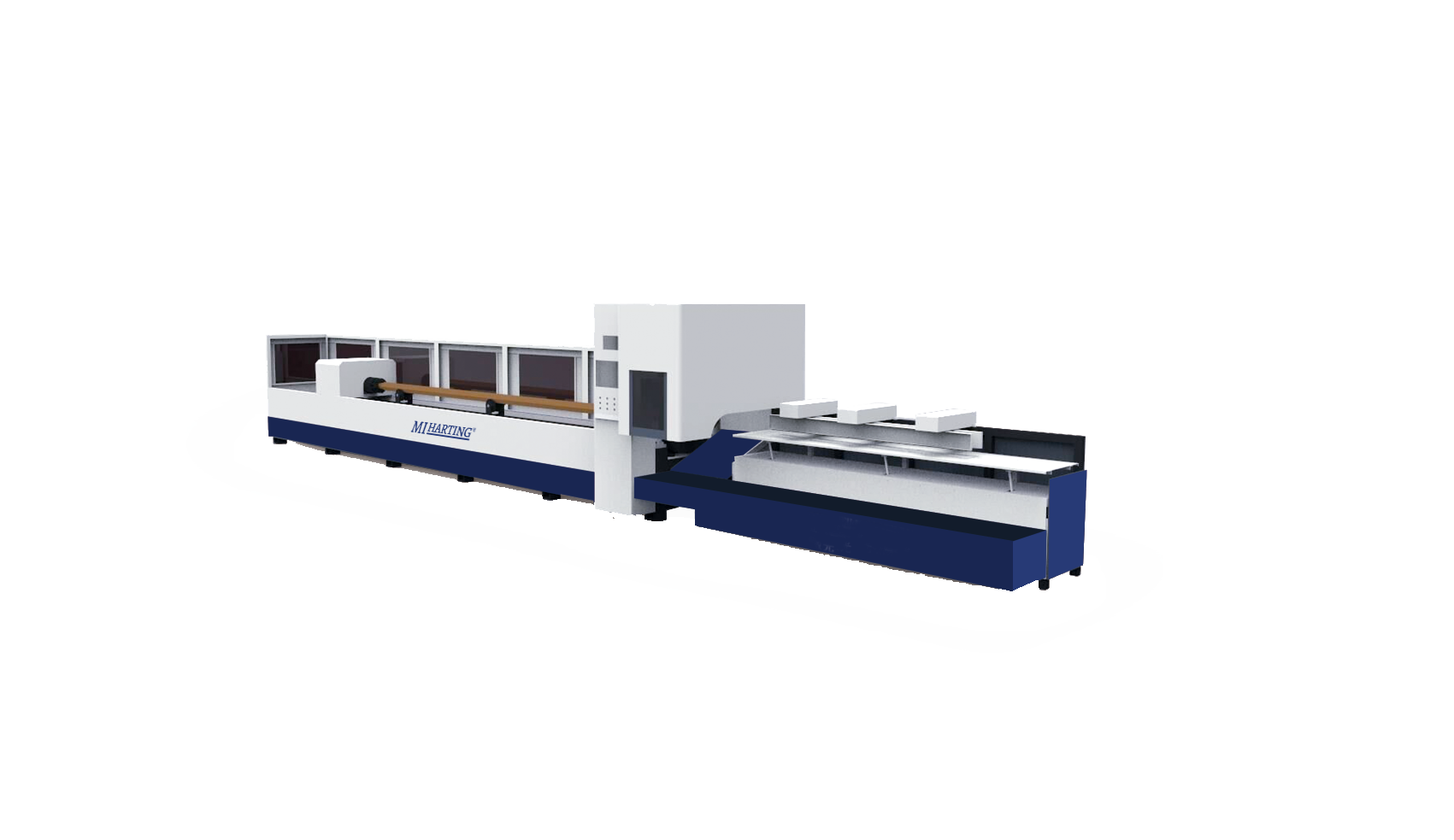

| Laser power | 1000W-15000W |

| Pipe length range | 3000mm/6000mm |

| Maximum tube wall cutting thickness | ≤6mm/12mm |

| Round tube diameter range | φ20-φ220mm |

| Square tube diameter range | 14mm-160mm |

| Positioning accuracy | ±0.03mm/m |

| Repeat positioning accuracy | ±0.02mm/m |

| Power requirement | AC 380V/50HZ |

| Cooling method | Water-cooled |

| Machine operation temperature | 0℃-40℃ |

| Machine running temperature | 5%-90% |

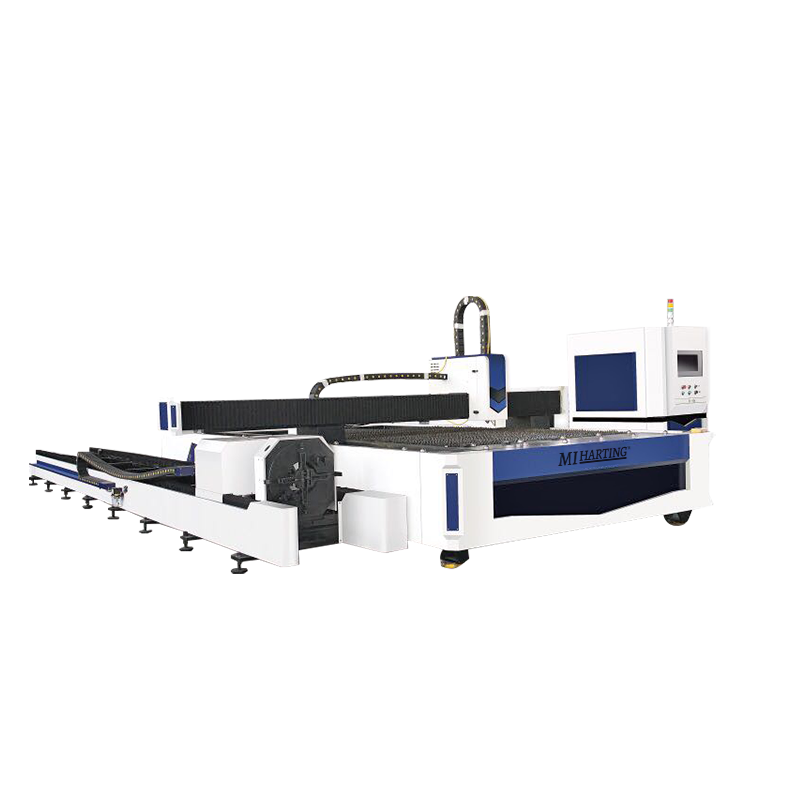

| Machining width option | 3000*1500mm |

| 4000*1500mm | |

| 4000*2000mm | |

| 6000*1500mm | |

| 6000*2000mm |

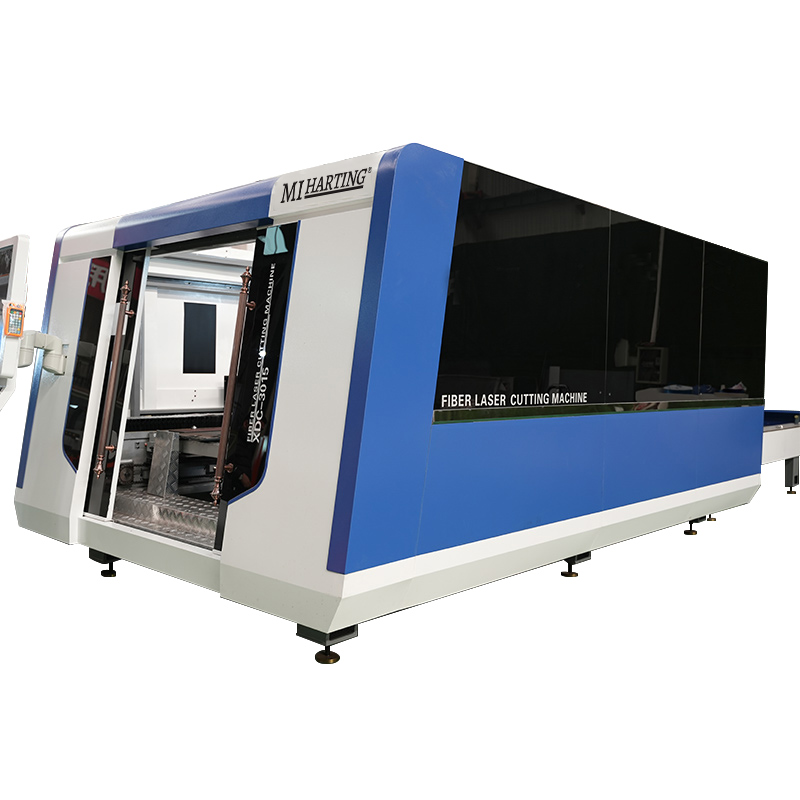

- SUPER THICK AND WIDE STEEL BED:

Steel bed has good shock absorptionan dsmalldeformation, which ensures the stability of long-term production. It can effectively counteract the force of frequent high-speed reversing and high acceleration and deceleration, which is the guarantee of stable quality and provides support for constant quality of laser cutting machine.

STRETCHED ALUMINUM GANTRY:

Using low pressure steel film casting process, the beam has high density, light weight, smooth surface equality, excellent integrity and rigidity. At the same time, it has good toughness, ductility and corrosion resistance.

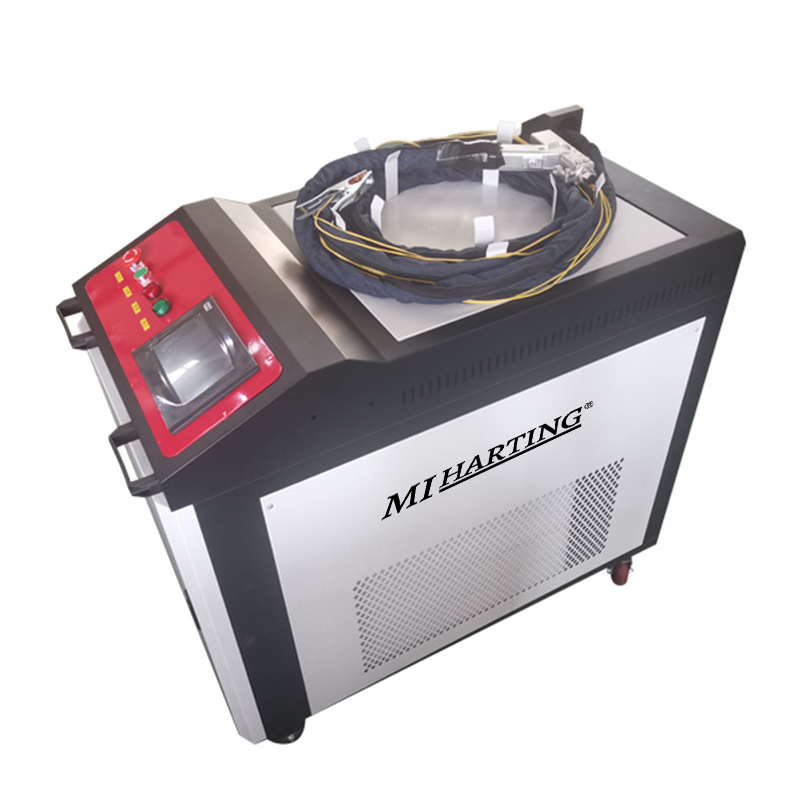

LASER CUTTING SYSTEM:

Intelligent visual control system, the operation interface is easier to understand, and the laser power, gas type and pressure can be adjusted intuitively; Intelligent edge searching,automatic positioning, easy to achieve efficient production. - JAPAN PANASONIC SERVO MOTOR:

The high precision servo motor can control the cutting speed and position, running smoothly and without vibration.

LASER CUTTING:

The laser head automatically avoids obstacles, suppresses vibrations, and enables multiple perforation patterns.