FEATURE

-

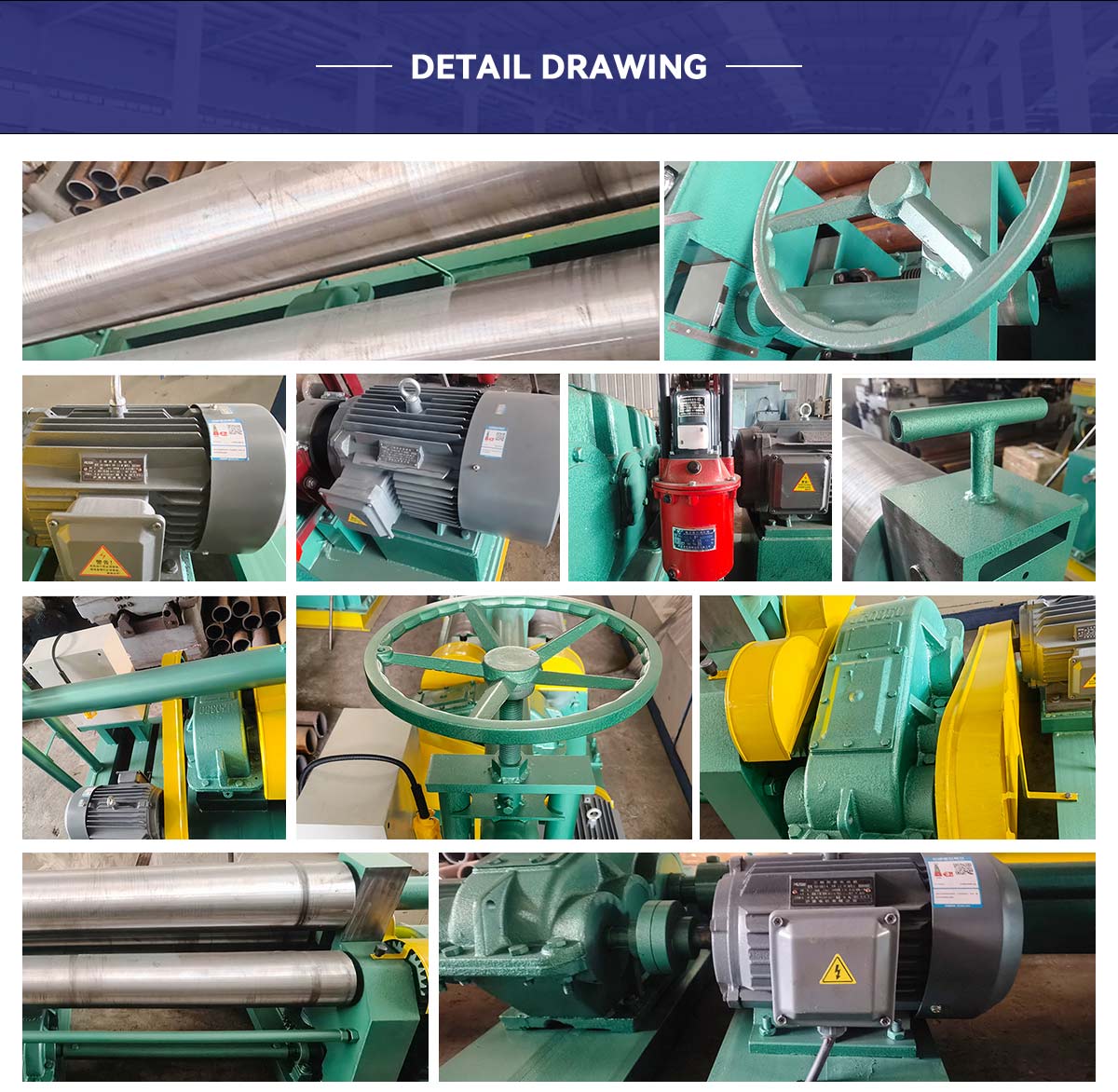

The main features of the mechanical three-roller asymmetric plate rolling machine: The structure of the machine is a three-roller asymmetrical type. The upper roller is the main drive, and the lower roller moves vertically up and down, and the lower roller gear meshes with the upper roller gear as the main drive; The side roller performs tilting and lifting movements and has dual functions of pre-bending and rounding. Compact structure, easy operation and maintenance.

-

This machine is suitable for bending and deforming metal sheets. It can roll round, arc-shaped and tapered workpieces within a certain range. It has a plate end pre-bending function. The two lower rollers of this model are driving rollers and can move horizontally. The upper roller is a driven roller that can move up and down, and the transmission shafts are connected by universal couplings.

-

Roll the plate according to the parameters specified by the plate rolling machine. The thickness of the plate is 20mm, the maximum length is 2500mm, and the yield limit of the plate rolling material is less than 250Mpa.

CNC CONTROL SYSTEM

| Model | Max.Thickness of plate (mm) | Max.Width of plate (mm) | Plate Yieid Limit (MPa) | Rolling Speed (m/min) | Min dia.of plate in full load(mm) | Dia.of Upper Roller (mm) | Dia.of Lower Roller(mm) | Space between of two Lower Rollers | Motor Power(kw) | Overall Dimensions L*W*H(mm) |

| W11-6*1500 | 6 | 1500 | 265 | 7.16 | 380 | 180 | 160 | 210 | 5.5 | 3310*1210*1330 |

| W11-6*2000 | 6 | 2000 | 265 | 7.16 | 380 | 180 | 160 | 220 | 5.5 | 3810*1210*1330 |

| W11-6*2500 | 6 | 2500 | 265 | 7.16 | 500 | 190 | 170 | 260 | 7.5 | 4310*1210*1330 |

| W11-6*3200 | 6 | 3200 | 265 | 6.46 | 500 | 240 | 200 | 310 | 11 | 5200*1400*1200 |

| W11-8*2000 | 8 | 2000 | 265 | 7.16 | 450 | 190 | 170 | 260 | 7.5 | 3810*1210*1330 |

| W11-8*2500 | 8 | 2500 | 265 | 6.46 | 500 | 240 | 200 | 310 | 11 | 4500*1420*1610 |

| W11-12*2000 | 12 | 2000 | 265 | 5 | 500 | 240 | 200 | 310 | 11 | 4050*1420*4610 |

| W11-12*2500 | 12 | 2500 | 265 | 5 | 750 | 260 | 220 | 330 | 11 | 5000*1500*1300 |

| W11-12*3000 | 12 | 3000 | 265 | 5 | 650 | 280 | 240 | 360 | 15 | 5500*1500*1300 |

| W11-16*2000 | 16 | 2000 | 265 | 5 | 750 | 260 | 220 | 330 | 11 | 4500*1500*1300 |

| W11-16*2500 | 16 | 2500 | 265 | 5 | 750 | 280 | 240 | 360 | 15 | 500*1500*1300 |

| W11-16*3200 | 16 | 3200 | 265 | 5 | 900 | 340 | 280 | 440 | 22 | 6300*1600*1900 |

| W11-20*2000 | 20 | 2000 | 265 | 5 | 750 | 280 | 240 | 360 | 15 | 4500*1500*1300 |

| W11-20*2500 | 20 | 2500 | 265 | 5 | 850 | 340 | 280 | 440 | 30 | 5600*1600*1900 |

| W11-25*2000 | 25 | 2000 | 265 | 5 | 850 | 340 | 280 | 440 | 30 | 5100*1600*1900 |

| W11-25*2500 | 25 | 2500 | 265 | 4.5 | 900 | 380 | 300 | 490 | 37 | 6000*4600*2150 |

| W11-30*2000 | 30 | 2000 | 265 | 4.5 | 900 | 380 | 300 | 490 | 37 | 5500*1460*2150 |

| W11-30*2500 | 30 | 2500 | 265 | 4.5 | 1100 | 460 | 380 | 600 | 45 | 6900*2300*2800 |

| W11-30*3000 | 30 | 3000 | 265 | 5 | 1200 | 460 | 400 | 600 | 45 | 7400*2300*2800 |

| W11-30*3200 | 30 | 3200 | 265 | 5 | 1200 | 500 | 400 | 600 | 45 | 7600*2300*2600 |

| W11-40*2000 | 40 | 2000 | 265 | 5 | 1200 | 480 | 400 | 600 | 45 | 6400*2300*2800 |